The proximity sensor has the characteristics of long service life, reliable operation, high repeat positioning accuracy, no mechanical wear, no sparks, no noise, and strong vibration resistance. It can be used as a limit, counting, positioning control, and automatic protection link in automatic control systems. It is widely used in machine tools, metallurgy, chemical industry, light textile and printing and other industries.

Before we talk about the application of the proximity sensor, let's first understand some of the main functions it has:

1. Inspection of the distance for stopping, starting, and passing positions of elevators, lifting devices; inspection of the position of vehicles to prevent collision; inspection of the set position of working machinery, the limit position of the movement of machines or parts; inspection of the stop position of rotary bodies, the open or closed position of valves; inspection of the position of the piston moving in a cylinder or hydraulic cylinder.

2. Dimension control device for cutting metal plates; automatic selection and identification of the length of metal parts; detection of the height of the stack during automatic loading and unloading; detection of the length, width, height and volume of the goods.

3. Detection of object presence includes checking for product packaging boxes on the production packaging line; checking for product parts.

4. Speed and velocity control control the speed of the conveyor belt; control the speed of rotating machinery; control the speed and revolution with various pulse generators.

5. Counting and control detection of the number of products flowing through the production line; revolution counting of high-speed rotating shafts or discs; part counting.

6. Detecting abnormal conditions such as the absence of bottle caps; determining product acceptance or rejection; checking for the absence of metal products in the packaging box; distinguishing between metal and non-metal parts; detecting the presence or absence of product labels; alarms for dangerous areas of cranes; automatic start and stop of safety escalators.

7. Automatic metering of products or parts; control of the number or flow by detecting the pointer range of the meter, instrument; detection of the level of the floating mark controlling the surface height, flow; detection of the iron floating mark in the stainless steel drum; control of the upper or lower limit of the instrument range; flow control, level control.

8. Identification of objects based on the recognition of the code on the carrier is and is not.

9. Information transmission ASI (bus) connection of devices at various positions of the sensor in the production line (50-100 meters) for data transmission back and forth, etc.

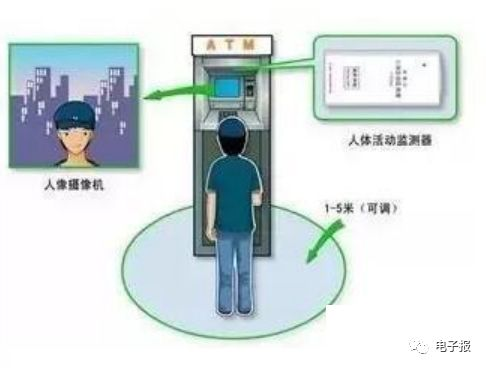

At present, proximity sensors are widely used in various fields such as aerospace, industrial production, transportation, and consumer electronics. Below are several typical application scenarios to help you open up some ideas for the application design of proximity sensors. The application of human proximity sensor in ATM monitoring is a control device used to detect the approach of the human body. It can accurately detect the approach of nearby people and is currently the best choice for alarm and status detection. Its sensing part has a high detection sensitivity to the movement of nearby people and has strong anti-interference ability due to the suppression of sound signals in the surrounding environment. The internal microcircuit chip is used for program control processing, which has a high detection sensitivity and trigger reliability. The detection and control parts are integrated, with low standby power consumption, switch signal output, and direct triggering of alarm recording. Since the sensitivity of human induction is continuously adjustable, this makes the human proximity sensor applicable to many different occasions. In terms of security and anti-theft, places such as data archives, finance, finance, museums, and treasuries are often equipped with anti-theft devices composed of various proximity sensors.

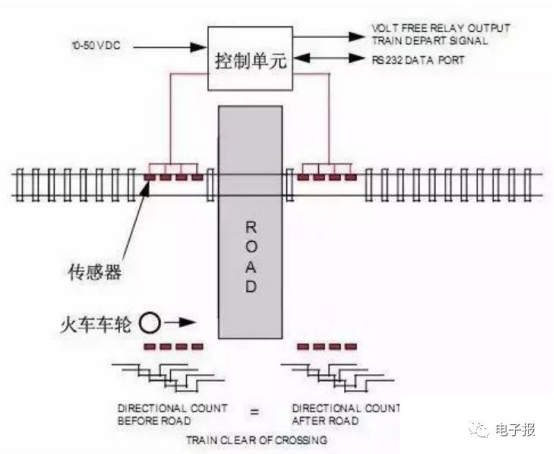

Application of Proximity Sensors in Aircraft Landing Gear System?The flight control system, landing gear system, and navigation system are the top three systems reported by airlines in the data of aircraft usage difficulties. Among them, landing gear system failures can easily cause aircraft to return to the airport, divert, and other abnormal events, causing economic losses to the company and hidden dangers to aviation safety. In the landing gear control system of general Airbus aircraft, digital electronic control systems are usually used. Its basic principle is to send the sensor signal to the control box (control computer), perform comprehensive operation and comparison, and then send instructions to the actuator. The control link is redundant control. The landing gear of modern civil aircraft includes two sets of systems for normal extension and emergency release. The landing gear control system uses electronic control in operation mode and is interlinked with other systems. Inductive proximity sensors are widely used to detect the position of the landing gear. Each landing gear has two main sensors, namely, the uplock sensor and the downlock sensor, which are used to connect the transmission position signal when the uplock and downlock are locked. This type of sensor is a magnetic resistance type proximity sensor, which is mainly composed of two parts: the sensor body and the sensor excitation plate. The sensor body converts electric energy into a magnetic field, and the excitation plate mainly plays a role in increasing the magnetic permeability. When the landing gear approaches the excitation plate to a certain distance, the magnetic permeability increases, and the sensor sends a signal to warn the component to indicate the position of the landing gear. The distance between them directly affects the accuracy of the indication, and the general adjustment requirements are also relatively strict. In addition, different models are slightly different, and the adjustment should also refer to the AMM manual of the model. The use of inductive proximity sensors to detect the position of the landing gear has improved the service life of the sensor. In addition, the information transmission and information sharing with the aviation electronic system are conveniently realized by the control computer. Application of Proximity Sensors in Railway Crossing Monitoring?Among all railway accidents, train collisions account for a large part and often have serious consequences. The use of proximity sensors to monitor the trains passing through the intersection has become an important link in improving the safety of railways. In practical application, the non-contact position measurement characteristics of the proximity sensor can be used to install them symmetrically at the two ends of the railway track of the intersection. When a train passes, the proximity sensor at both ends of the railway track can detect the change caused by the wheels passing through. By analyzing the sensor signal by the intersection monitoring microprocessor system, it is possible to judge the direction of vehicle travel and the state at the time of crossing (whether it passes or stops). ***Finally, the information is sent to the traffic control center by means of cables or wireless communication, so as to adjust the train.

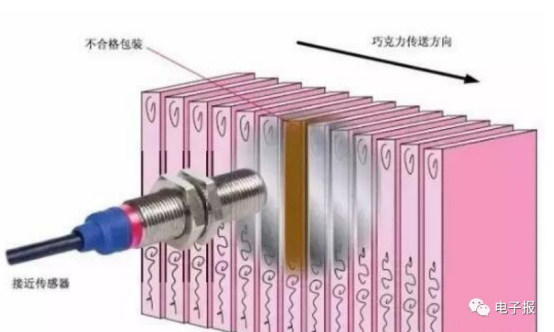

Application of Proximity Sensor in Automatic Packaging Machinery The mechanization of production manufacturing has given birth to the demand for automatic packaging technology, and the way of manual packaging can no longer meet the batch production operation. Automatic packaging machinery can complete a series of packaging process flows for items under the guidance of the control system, improving the efficiency of product packaging and reducing packaging costs, but there are still inevitable loopholes. To this end, automatic packaging detection has become an important link to ensure the quality of packaging. Among them, for the case of magnetic substances in the packaging process, using a proximity sensor for non-contact detection is a common way. The coil inside the proximity sensor can produce an alternating magnetic field. When the detected magnetic object is in this environment, it will form a eddy current inside due to the principle of electromagnetic induction. When the magnetic field generated by the eddy current is large enough, it will feedback and change the original circuit parameters of the proximity sensor, thus producing a signal output. Therefore, using a proximity sensor can identify whether there are magnetic or easily magnetized substances within a certain range nearby. In some automatic packaging processes, such as the packaging of chocolate metal foil paper, through the detection of the existence of magnetic substances by the proximity sensor, it can be determined whether there are packaging errors or process omissions of unqualified products, thereby improving the quality of packaging.

Application of Proximity Sensor in Robot Hand gripper Robot hand gripper is a mechanical structure part with multiple degrees of freedom, which can flexibly grasp objects. It can be used in various industrial automation production, assembly and operation, and can perform information detection, object collection and reconnaissance, bomb disposal and other tasks in high-risk environments. Robot hand grippers generally adopt clamp-shaped structure, and the opening and closing of the clamp is used to grasp objects. Therefore, the precise measurement and control of the "钳口" opening and closing degree is a key factor affecting the success of the grasping process. Since the proximity sensor can sense the change of distance and position, it is also a common sensor used in robot hand grippers to measure the opening and closing situation. It uses the change of magnetic field and the relative position relationship with the measured metal parts to measure. Usually, the sensor is installed on one of the clamps of the gripper. When grasping an object, the proximity sensor can judge the distance between the two (clamps) by sensing the change of the size of the magnetic field. Thus, it can be compared with the set value, adjust the size of the gripper opening, and avoid grasping the air or damaging the object.

Application of capacitive proximity sensor in automotive electronicsThe demand for proximity detection sensors in the field of automotive electronics application has been steadily increasing. The possible applications of proximity detection in the automotive electronics industry are endless, for example: Automotive door control: detect the hand approaching the door handle, and then start the unlocking procedure when the palm is close to the screen surface, it can illuminate and wake up the touch screen. When the palm is close to the sensor, it can turn on/off the interior lighting of the car. Turn on/off the device by detecting the simple movement of the palm in the air. Detect large obstacles around the car during parking?摇Against a variety of different automotive electronic application needs, there are a variety of proximity detection methods, such as capacitive sensing, infrared, ultrasonic, optical, etc. For proximity detection from 5mm to 300mm range, capacitive sensing technology has many advantages over other technologies: excellent reliability, simple mechanical design, low power consumption and low cost. An example of the application of capacitive proximity detection is in the automotive door access system (see the picture below). The proximity sensor for detecting the hand approaching is located inside the car door handle (1). Once a nearby object is detected, the main control unit (2) sends a wake-up signal through a low-frequency antenna (3); this signal activates the car key transmitter (4). The car key transmitter then exchanges information with the RFID receiver (5); if the encoded information matches the main control unit (2), the car door lock opens. The whole process of proximity detection and ID recognition takes about a few tenths of a second. This means that the door lock has already opened by the time the hand拉 the door handle. The advantage of using proximity detection in automotive door access systems instead of touch detection is that it can抢先 identify the owner of the car, resulting in the door lock being in the open state before the door is pulled.

Statement: The above content is all from the Internet, if it does not match the actual situation or there is an infringement, please contact us to delete.

Original author of the article: Electronic newspaper

Article source: Sensor Expert Network

Original link: https://www.sensorexpert.com.cn/article/427469.html